Understanding how much load a scaffold tower safely can support is crucial for ensuring the safety of workers and preventing accidents on construction sites.

The load capacity is influenced by several key factors, including material construction, design and structure, and manufacturer specifications.

When transporting scaffold towers, logistics play a vital role in maintaining the integrity of the structure, thereby ensuring it remains safe to use.

Key Takeaways

- The safe load capacity of a scaffold tower is critical for worker safety.

- Material construction and design affect the load capacity.

- Manufacturer specifications must be consulted to determine safe load limits.

- Logistics during transportation impact the safety of scaffold towers.

- Regular inspections are necessary to maintain scaffold tower integrity.

Understanding Scaffold Tower Load Capacity

Scaffold towers are designed to handle different types of loads, and understanding these capacities is vital for safe working practices. The load capacity of a scaffold tower is not just about the weight it can bear but also about the type of load it is subjected to.

Types of Loads: Dead Load vs Live Load

To understand the load capacity of a scaffold tower, it’s essential to differentiate between dead loads and live loads. Dead loads refer to the weight of the scaffold itself, as well as any permanent fixtures or equipment attached to it. On the other hand, live loads include the weight of workers, tools, materials, and any other equipment used on the platform.

Class 1, 2, and 3 Load Classifications

Scaffold towers are classified into different load categories based on their load capacity. These classifications help in determining their safe load capacity. For instance, Class 1 scaffold towers are designed for heavy-duty applications, while Class 3 towers are suited for light-duty tasks. Understanding these classifications is crucial for selecting the right scaffold tower for specific tasks, ensuring that it can safely support the required load.

By recognising the differences between dead and live loads and understanding the load classifications, users can ensure the safe and effective use of mobile scaffold platforms and portable tower scaffolds.

Factors Affecting Scaffold Tower Safely Support Limits

Understanding the factors that affect the safe load capacity of scaffold towers is crucial for ensuring worker safety on construction sites. Several key elements contribute to the overall stability and safety of these structures.

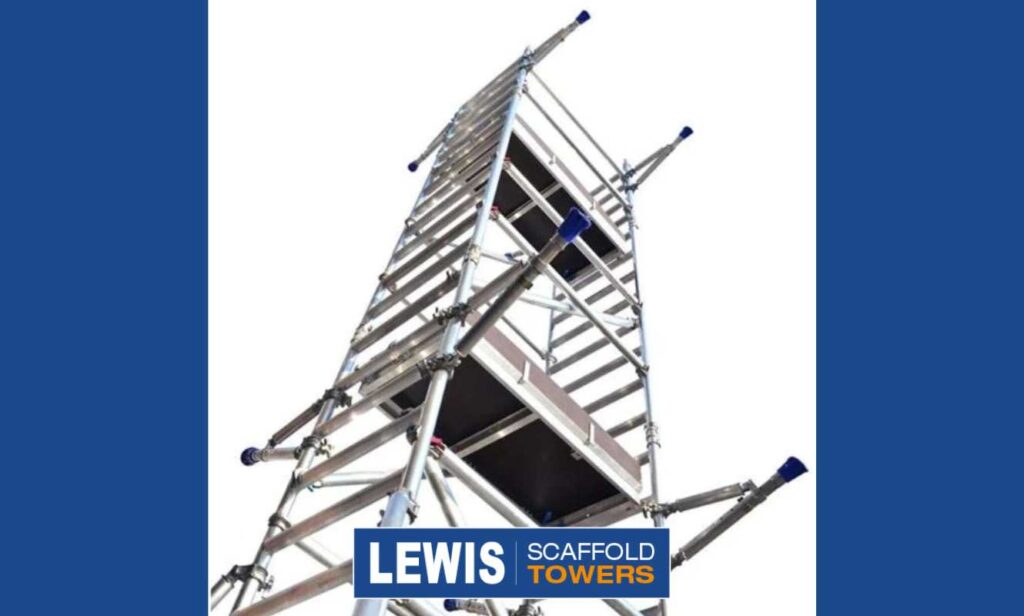

Tower Height and Base Width Ratio

The ratio of a scaffold tower’s height to its base width is a critical factor in determining its stability. A taller tower with a narrower base is more susceptible to tipping or collapse. It is essential to ensure that the tower’s dimensions are appropriately proportioned to support the intended load.

Material Construction Quality

The quality of materials used in the construction of scaffold towers significantly impacts their safe load capacity. High-quality materials can support greater weights and withstand environmental stresses better than lower-quality materials.

Environmental Conditions

Environmental conditions, including wind loads and surface stability, play a crucial role in the safe operation of scaffold towers. Wind can exert significant forces on these structures, potentially leading to instability or collapse if not properly accounted for.

Wind Load Considerations

Wind load is a critical environmental factor that must be considered when erecting and using scaffold towers. The towers must be designed and secured to withstand expected wind forces in the area.

Surface Stability Impact

The stability of the surface on which a scaffold tower is erected is also vital. Uneven or unstable surfaces can compromise the tower’s stability, increasing the risk of accidents.

| Factor | Impact on Scaffold Tower | Mitigation Measure |

|---|---|---|

| Tower Height and Base Width Ratio | Affects stability and risk of tipping | Ensure appropriate dimensions and proportion |

| Material Construction Quality | Influences safe load capacity and durability | Use high-quality materials in construction |

| Wind Load | Can cause instability or collapse | Design and secure towers to withstand wind forces |

| Surface Stability | Affects tower stability and safety | Ensure the surface is even and stable |

Standard Load Capacities for Common Scaffold Tower Types

Different materials used in scaffold towers, such as aluminium, fibreglass, and steel, have distinct load-bearing capacities. Understanding these capacities is crucial for ensuring safety on construction and maintenance sites.

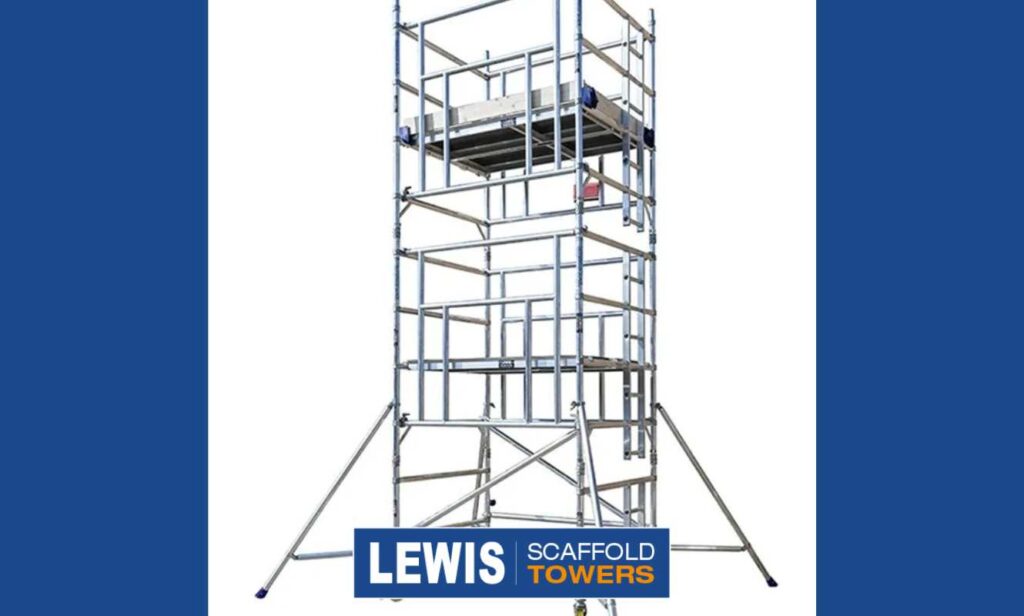

Aluminium Scaffold Towers

Aluminium scaffold towers are known for their lightweight and corrosion-resistant properties, making them ideal for tasks that require mobility and ease of setup. Typically, aluminium towers have a load capacity that is suitable for most general construction tasks.

Steel Scaffold Towers

Steel scaffold towers are renowned for their high strength and durability, allowing them to support substantial weights. They are often used in heavy-duty construction projects where high load capacities are required.

Single vs Double Width Towers

The design of the scaffold tower, including whether it is a single or double width configuration, also significantly affects its load capacity.

- Single width towers are more suitable for tasks that require less equipment and personnel.

- Double width towers offer greater stability and can support more weight, making them ideal for complex tasks or when using heavy equipment.

When selecting a scaffold tower, it’s essential to consider both the material and the design to ensure it meets the specific needs of your project, enhancing both safety and efficiency.

How to Calculate Maximum Safe Load for Your Scaffold Tower

The safe utilisation of scaffold towers hinges on accurately determining their maximum load-bearing capacity. This involves understanding several critical factors that contribute to the overall safety and stability of the structure.

Understanding Working Load Limit (WLL)

The Working Load Limit (WLL) is the maximum weight that a scaffold tower is designed to support safely. It’s a crucial figure that must be adhered to, to prevent overloading and potential collapse. When using transport scaffold towers or portable tower scaffolds, it’s vital to know the WLL as specified by the manufacturer.

Calculating Personnel and Equipment Weight

To ensure the scaffold tower is not overloaded, calculate the total weight of personnel and equipment that will be on the tower. This includes workers, tools, and materials. Accurate calculation is key to maintaining the scaffold tower safely.

Using Load Charts and Manufacturer Guidelines

Load charts and manufacturer guidelines provide essential information for determining the safe load capacity. Always refer to these resources when assessing the load-bearing capacity of your scaffold tower safely. By doing so, you can ensure compliance with safety standards and regulations.

Safety Regulations and Compliance for Scaffold Tower Loading

The safe utilisation of scaffold towers is contingent upon compliance with specific safety guidelines and regulations. Various countries have their own set of standards and regulations governing the use of scaffold towers.

OSHA Requirements in the United States

In the United States, OSHA (Occupational Safety and Health Administration) sets forth guidelines that employers must follow. These include regular inspections and proper training for workers using scaffold towers.

British Standards and European Norms

In the UK, British Standards provide a framework for the safe design, construction, and use of scaffold towers. Similarly, European Norms regulate scaffold tower safety across Europe.

Documentation and Inspection Requirements

Regular documentation and inspections are critical for ensuring compliance. Key requirements include:

- Daily inspections before use

- Regular maintenance records

- Training records for personnel

By adhering to these regulations and maintaining thorough documentation, employers can significantly reduce the risk of accidents involving scaffold towers.

Using Scaffold Tower Safely in Various Work Environments

Ensuring the safe use of scaffold towers involves understanding the specific demands of different work environments, whether indoors or outdoors. The versatility of scaffold towers means they can be adapted to various settings, but this requires careful planning and execution.

Indoor vs Outdoor Considerations

When using scaffold towers outdoors, it’s crucial to consider environmental factors such as wind and weather conditions. In contrast, indoor use may require attention to factors like ceiling height and floor surface.

Adjusting for Uneven Surfaces

Uneven surfaces can pose significant challenges, necessitating adjustments to the tower’s configuration to ensure stability. This may involve using levelling devices or adjusting the tower’s base.

Multiple Workers on a Single Tower

When multiple workers are using a single tower, it’s essential to ensure that the total load does not exceed the tower’s safe load capacity. A simple calculation can help determine this:

| Worker/Activity | Weight (kg) |

|---|---|

| Worker 1 | 80 |

| Worker 2 | 70 |

| Equipment | 50 |

| Total | 200 |

Transportable Scaffold Systems: Moving and Delivery

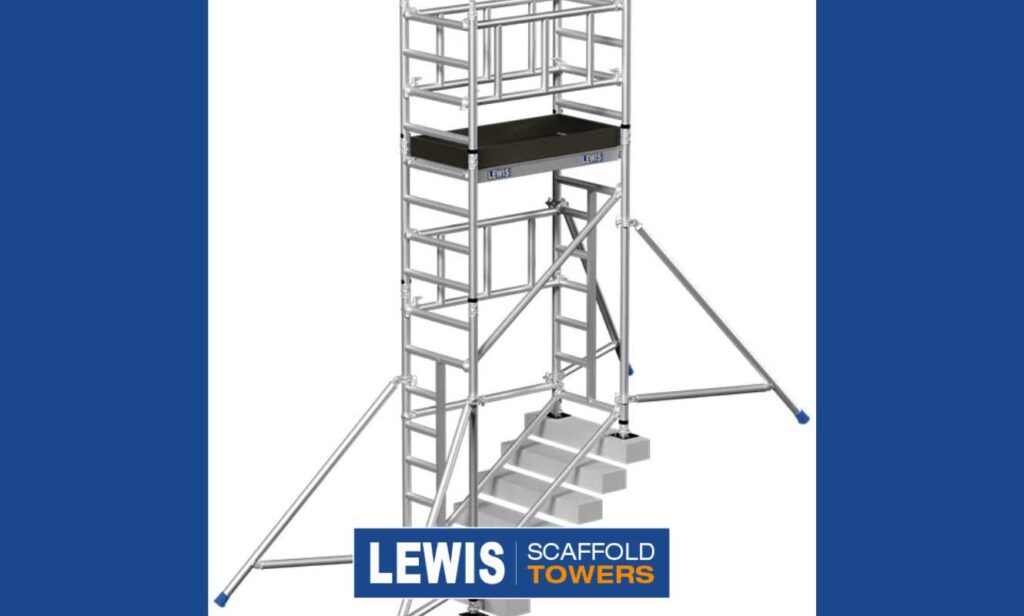

Transportable scaffold systems are designed for easy relocation, but their movement requires careful planning. The process involves several logistical considerations to ensure safe and efficient transportation.

Scaffold Tower Transportation Methods

The method of transporting scaffold towers depends on their size, weight, and the distance to be covered. Common methods include using vehicles, cranes, or manual handling for smaller towers.

Vehicle Requirements for Scaffold Tower Delivery

Vehicles used for transporting scaffold towers must meet specific requirements, including adequate space, secure tie-downs, and compliance with road regulations. The size and weight of the tower will dictate the type of vehicle needed.

Portable Tower Scaffolds: Assembly After Transport

Upon arrival at the construction site, portable tower scaffolds must be assembled correctly. This involves following the manufacturer’s instructions and ensuring the tower is level and securely positioned.

Industrial Scaffold Towers

Lewis towers are BSi kitemarked to EN1004. Making and selling high-end quality industrial towers and other access equipment since 2004!

Scaffold Tower Logistics for Construction Sites

Effective logistics planning is crucial for the timely delivery and setup of scaffold towers. This includes coordinating with site managers and ensuring that the necessary equipment and personnel are available.

| Transportation Method | Advantages | Disadvantages |

|---|---|---|

| Vehicle Transport | Flexible, can reach most locations | Dependent on road conditions, requires secure tie-downs |

| Crane Transport | Ideal for heavy or large towers, can navigate difficult terrain | Requires crane availability, can be costly |

| Manual Handling | Cost-effective for small towers, doesn’t require special equipment | Limited by tower size and weight, labour-intensive |

Final Thoughts

Ensuring the safe load capacity of scaffold towers is a multifaceted task that involves understanding various factors, complying with safety regulations, and using the towers in appropriate work environments. By considering factors such as material construction, environmental conditions, and compliance with safety regulations, workers can use scaffold towers safely and effectively.

When planning to use a scaffold tower, it is essential to consider the logistics of the operation, including the transportation and assembly of portable tower scaffolds. Effective scaffold tower logistics can help prevent accidents and ensure a smooth workflow. By following the guidelines outlined in this article, construction professionals can ensure the safe and efficient use of scaffold towers on their sites, ultimately supporting the safe completion of projects.

Using a scaffold tower safely requires careful planning, attention to detail, and a commitment to adhering to safety regulations. By prioritising scaffold tower safety and taking a proactive approach to risk management, construction professionals can minimise the risks associated with scaffold tower usage.

FAQ

What is the difference between dead load and live load in the context of scaffold towers?

Dead load refers to the weight of the scaffold tower itself, including any permanent fixtures or equipment attached to it. Live load, on the other hand, includes the weight of workers, tools, materials, and any other equipment used on the platform.

How does the height-to-base-width ratio of a scaffold tower affect its safe load capacity?

A taller scaffold tower with a narrower base is more susceptible to tipping or collapse. Therefore, the ratio of the tower’s height to its base width is critical in determining its safe load capacity.

What are the advantages of using aluminium scaffold towers?

Aluminium scaffold towers are lightweight and corrosion-resistant, making them suitable for a variety of tasks. They are a popular choice for many construction projects due to their ease of use and durability.

How do I calculate the maximum safe load for my scaffold tower?

To calculate the maximum safe load, you need to understand the Working Load Limit (WLL) of your scaffold tower, which is the maximum weight that the scaffold is designed to support safely. You should also calculate the total weight of all personnel and equipment that will be on the tower.

What safety regulations should I comply with when using scaffold towers?

In the United States, you should comply with OSHA (Occupational Safety and Health Administration) guidelines. In the UK, you should follow British Standards, which provide a framework for the safe design, construction, and use of scaffold towers.

Can scaffold towers be used on uneven surfaces?

Yes, scaffold towers can be used on uneven surfaces, but you may need to adjust the tower’s configuration to ensure stability. It’s essential to follow the manufacturer’s guidelines and take necessary precautions to prevent accidents.

How should I transport scaffold towers to the construction site?

The method of transportation depends on the size and weight of the scaffold tower, as well as any relevant regulations governing transportation. You should carefully plan the transportation to prevent damage to the tower and ensure safe and efficient logistics.

What are the benefits of using fibreglass scaffold towers?

Fibreglass scaffold towers offer excellent electrical insulation, making them suitable for use in environments where electrical safety is a critical consideration.

How often should I inspect my scaffold tower?

Regular inspections are crucial to ensure the safe use of scaffold towers. You should inspect your scaffold tower before each use and follow the manufacturer’s guidelines for maintenance and inspection.

Can multiple workers use a single scaffold tower?

Yes, but you must ensure that the total load does not exceed the tower’s safe load capacity. You should calculate the total weight of all personnel and equipment and follow the manufacturer’s guidelines.

What is the role of load charts in determining the safe load capacity of a scaffold tower?

Load charts provide valuable information for determining the safe load capacity of a specific scaffold tower. They help you understand the maximum weight that the scaffold can support safely.