How to transport scaffold towers between jobs is a crucial aspect of the construction industry, requiring careful planning and execution.

The process of moving scaffolding equipment from one site to another can be time-consuming and labour-intensive, with potential risks to workers and the general public if not done correctly. Efficient transportation of scaffold towers is essential to ensure that construction projects are completed on schedule and within budget.

It may interest you to check out how LEWIS will transport scaffold towers to you when you buy.

Key Takeaways

- Efficient transportation of scaffold towers is crucial for construction projects.

- Moving scaffolding equipment can be time-consuming and labour-intensive.

- Proper planning is necessary to minimise risks during transportation.

- Scaffold tower transportation requires careful execution to avoid accidents.

- The construction industry relies heavily on the safe transportation of scaffolding.

Understanding Different Types of Scaffold Towers

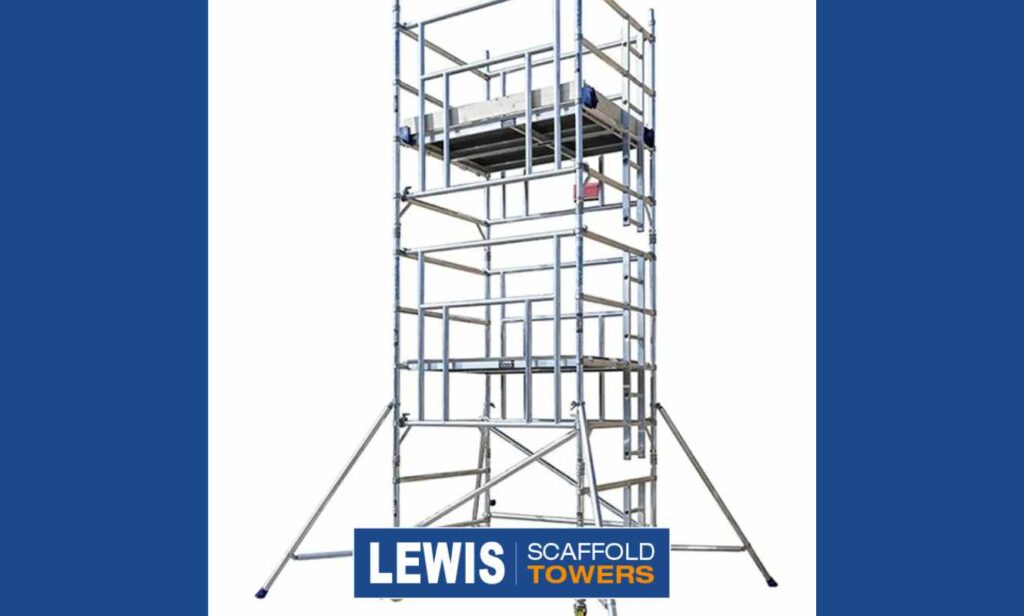

When it comes to scaffold towers, understanding the different types is essential for selecting the right equipment for your project. Scaffold towers are temporary structures used in construction, maintenance, and repair projects, offering a safe working platform at heights.

The primary distinction between scaffold towers lies in their mobility and stability features. This brings us to the main types: mobile and static scaffold towers.

Mobile vs. Static Scaffold Tower Designs

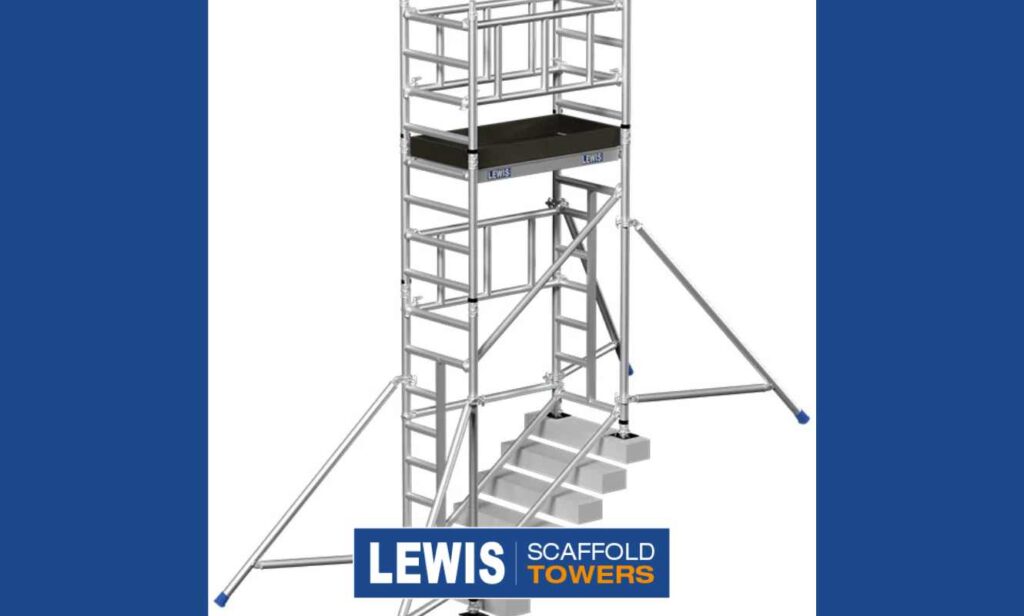

Mobile scaffold towers are designed for ease of movement around a worksite. They are ideal for projects that require frequent relocation of the scaffold. On the other hand, static scaffold towers are fixed in one position, providing a stable working platform for tasks that do not require frequent movement.

The choice between mobile and static scaffold towers depends on the project’s specific needs. For instance, mobile scaffold platforms are perfect for tasks that require flexibility and movement.

Weight and Dimension Considerations

Understanding the weight and dimensions of scaffold towers is crucial for their safe transportation and use. The size and weight of the scaffold tower will influence the method of transportation, including the type of vehicle required for scaffold tower delivery.

- Consider the height and width of the scaffold tower when assembled.

- Assess the weight of the tower, including all components and accessories.

- Ensure that the transportation method can accommodate the tower’s dimensions and weight.

By considering these factors, you can ensure that your scaffold tower is transported safely and efficiently, meeting the needs of your project.

How to Transport Scaffold Towers Efficiently

The logistics of moving scaffold towers between job sites can be complex, but there are strategies to simplify the process. Efficient transportation is crucial for maintaining project timelines and budgets.

Vehicle Selection for Different Tower Sizes

Choosing the right vehicle is pivotal for transporting scaffold towers efficiently. The size and weight of the scaffold tower dictate the type of vehicle required.

Vans and Small Commercial Vehicles

For smaller scaffold towers, vans and small commercial vehicles are often sufficient. These vehicles are ideal for navigating through urban areas and can be more cost-effective.

Flatbed Trucks and Trailers

Larger scaffold towers require flatbed trucks or trailers. These vehicles provide the necessary space and stability for transporting bulky equipment.

Specialised Scaffold Transportation Equipment

Beyond standard vehicles, specialised equipment can enhance the transportation of scaffold towers. This includes scaffold racks and custom transport solutions designed to secure and protect the equipment during transit.

Scaffold Racks and Carriers

Scaffold racks and carriers are designed to hold scaffold components securely. They help in organising the equipment and preventing damage during transportation.

Custom Transport Solutions

For unique or oversized scaffold towers, custom transport solutions are available.

By selecting the appropriate vehicle and utilising specialised equipment, construction projects can ensure the efficient and safe transportation of scaffold towers.

Preparing Scaffold Towers for Transportation

Preparing scaffold towers for transportation involves a series of crucial steps that impact both safety and operational efficiency. Whether you’re dealing with portable tower scaffolds or more complex scaffold structures, the preparation phase is critical to ensuring that the equipment arrives at its destination in good condition and ready for use.

Disassembly Best Practices

Disassembling scaffold towers requires careful planning and execution. It’s essential to follow a systematic approach to dismantle the structure, starting from the top and working downwards. This method helps prevent damage to components and ensures worker safety.

Component Organisation Systems

Using a component organisation system can significantly streamline the disassembly process. By categorising and storing components in labelled containers, you can reduce the risk of losing parts and make reassembly more efficient.

Tools and Equipment Needed

Having the right tools and equipment on hand is vital for efficient disassembly. This includes wrenches, pliers, and other specialised tools designed for scaffold tower disassembly.

Securing and Protecting Components

Once disassembled, securing and protecting scaffold tower components is crucial to prevent damage during transit. This involves using appropriate strapping and tie-down techniques, as well as protecting components from weather conditions.

Strapping and Tie-Down Techniques

Effective strapping and tie-down techniques are essential to securing scaffold components during transportation. Using high-quality straps and ensuring that components are tightly secured can prevent shifting and potential damage.

Weather Protection During Transit

Protecting scaffold components from weather conditions such as rain or extreme temperatures is vital. Using waterproof covers or tarps can help maintain the integrity of the equipment.

By following these guidelines for preparing scaffold towers for transportation, you can ensure that your equipment is moved safely and efficiently, reducing the risk of damage and ensuring compliance with safety regulations when moving scaffold towers.

Safety and Legal Requirements for Scaffold Tower Transport

The safe transportation of scaffold towers is crucial for preventing accidents and complying with legal requirements. Scaffold towers, when not properly secured during transport, can pose significant risks to other road users and pedestrians. Therefore, understanding and adhering to safety and legal standards is paramount.

Load Securing Guidelines and Regulations

Securing scaffold towers during transportation is critical to prevent shifting or falling off vehicles. Regulations, such as those outlined in the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) and national guidelines, provide detailed requirements for load securing. It is essential to use appropriate tie-downs and ensure that the load is evenly distributed and properly covered.

Oversize Load Considerations

Scaffold towers can often be oversized loads, requiring special considerations during transport. Oversize loads may need escorts, special permits, and route planning to avoid obstacles and low-clearance areas.

Permits and Special Requirements

Transporting oversized scaffold towers typically requires obtaining special permits from local authorities. These permits often come with specific conditions, such as travel restrictions to certain times of the day or night, and requirements for escort vehicles.

Route Planning for Large Scaffold Systems

Effective route planning is vital for the successful transportation of large scaffold systems. This involves identifying the most suitable routes, avoiding height restrictions, weight limits, and other potential obstacles. Utilising GPS and route planning software can significantly aid in the transport scaffold towers process.

By adhering to these safety and legal requirements, construction companies can ensure the safe and compliant transportation of scaffold towers, minimising risks to both their personnel and the general public.

Cost-Effective Scaffold Tower Transportation Strategies

Optimising scaffold tower transportation is key to enhancing operational efficiency on construction sites. Effective logistics management can lead to significant cost savings and improved project timelines. When it comes to transporting scaffold towers, several strategies can be employed to ensure cost-effectiveness.

Comparing Transport Scaffold Towers Methods

Different transportation methods have varying costs and benefits. The choice between using a company-owned vehicle, hiring a transport service, or utilising a third-party logistics provider depends on several factors, including the size and weight of the scaffold towers, the distance to be covered, and the urgency of the delivery.

Time vs. Cost Analysis

A thorough analysis of time versus cost is essential when comparing transportation methods. For instance, hiring a specialised transport service might be more expensive upfront but could save time and reduce labour costs in the long run. As one logistics expert notes, “The right transportation method can make all the difference in meeting project deadlines.” Time is money, especially in construction projects, where delays can lead to significant additional costs.

Fuel Efficiency Considerations

Fuel efficiency is another critical factor to consider when transporting scaffold towers. Vehicles with better fuel efficiency can significantly reduce transportation costs, especially for long-distance hauls. According to a recent study, optimising routes and using fuel-efficient vehicles can lead to cost savings of up to 15%. Investing in fuel-efficient transport options can thus be a cost-effective strategy.

Rental vs. Purchase of Transport Equipment

The decision to rent or purchase transport equipment depends on the frequency of use and the specific needs of the project. Renting can be a cost-effective option for one-off or infrequent transports, while purchasing might be more economical for regular or large-scale operations. Here you discover how to choose the best scaffold towers for your needs.

When to Invest in Dedicated Transport Systems

Investing in dedicated transport systems can be beneficial for companies that frequently transport scaffold towers. This can include customised vehicles and equipment designed specifically for transport scaffold towers logistics. As noted by a construction company manager, “Having our own transport system has streamlined our operations and reduced costs in the long term.”

Sharing Transport Scaffold Towers Resources Between Companies

Another cost-effective strategy is sharing transport resources between companies. This collaborative approach can reduce the number of journeys needed, thus lowering overall transportation costs. It also promotes a more sustainable approach to logistics by reducing carbon emissions.

In conclusion, implementing cost-effective scaffold tower transportation strategies requires careful consideration of various factors, including transportation methods, fuel efficiency, and the rental or purchase of transport equipment. By adopting the right strategies, construction companies can significantly reduce their transportation costs and enhance their operational efficiency.

Efficient Scaffold Tower Transportation: A Key to Successful Projects

Transporting scaffold towers between jobs requires careful planning, specialized equipment, and a thorough understanding of safety regulations. By understanding the different types of scaffold towers and their transportation needs, companies can ensure efficient and safe delivery.

Effective transport scaffold towers involve selecting the right vehicle, preparing the towers for transportation, and securing the load to prevent damage or accidents. Companies like HSS Hire have developed specialised equipment for scaffold tower delivery, making the process more efficient.

By following the guidelines outlined in this article, construction companies can minimize delays, reduce costs, and ensure compliance with safety regulations. Ultimately, efficient scaffold tower transportation is crucial to the success of construction projects, enabling workers to complete tasks safely and effectively.

Transport Scaffold Towers FAQ

What are the most common challenges when transporting scaffold towers?

The most common challenges when transporting scaffold towers include navigating through tight spaces, dealing with varying road conditions, and ensuring the tower is properly secured to prevent damage or accidents during transit.

How do I choose the right vehicle for transporting a scaffold tower?

To choose the right vehicle, consider the size and weight of the scaffold tower, as well as the distance it needs to be transported. Vans, flatbed trucks, and custom transport solutions are available options, each with their own advantages and disadvantages.

What are the best practices for disassembling a scaffold tower for transport?

Best practices include following the manufacturer’s instructions, removing any loose components, and securing the remaining parts to prevent damage. It’s also essential to inspect the tower for any damage before disassembling it.

How can I ensure the scaffold tower is properly secured during transport?

To secure the scaffold tower, use suitable tie-downs and restraints, such as straps or chains, to prevent movement during transit. Make sure to follow the manufacturer’s guidelines and relevant regulations, such as those related to load securing.

What are the regulations surrounding oversize load transport?

Oversize load regulations vary by country and region, but generally, they require special permits, escort vehicles, and route planning to ensure safe passage. It’s crucial to familiarise yourself with the relevant regulations before transporting an oversize load.

Can I rent transport scaffold towers equipment, or should I purchase it?

Renting transport equipment can be a cost-effective option, especially for infrequent or one-off jobs. However, if you regularly transport scaffold towers, purchasing equipment might be more economical in the long run. Consider your specific needs and budget when making a decision.

How can I reduce the cost of transporting scaffold towers?

To reduce costs, consider sharing transport resources with other contractors or companies, comparing transportation methods, and optimising your route planning. Additionally, investing in reusable and durable transport equipment can help minimise expenses.

What are the benefits of using mobile scaffold platforms?

Mobile scaffold platforms offer greater flexibility and ease of movement, making them ideal for jobs that require frequent repositioning. They can also reduce the need for disassembly and reassembly, saving time and labour costs.

How can I protect my scaffold tower from weather damage during transport?

To protect your scaffold tower from weather damage, use weather-resistant coverings or tarps, and ensure the components are properly secured to prevent water ingress or damage from wind or rain.