Our folding toe-board set stops users from accidentally killing people on site by kicking off tools.

It serves as a barrier around your platform.

Table of Contents

Watch the Video Instead

Step 1: Cutting the Wood

Using the large sheets of wood, we can cut two long sheets to the perfect size for our platforms and staging boards.

As with most things that need cutting, there are off-cuts.

As a sustainable scaffold tower manufacturer, we reuse our off-cuts.

Step 2: Placing Off-Cuts into the Machine

Off-cuts are placed at the centre point of the machine.

Once securely placed, it’s clamped into place to prevent it from moving during cutting.

Now that it’s secured, it’s time to start the machine.

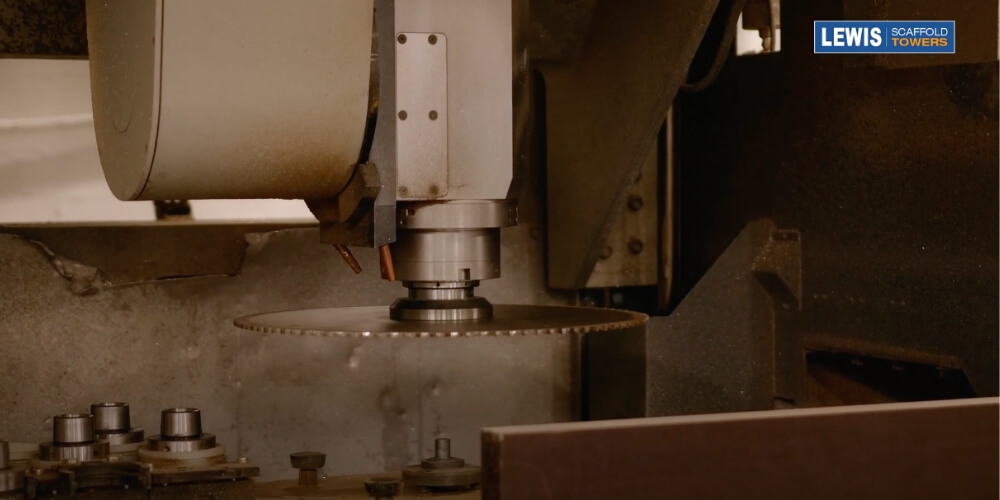

It starts with the turret head picking up a blade in preparation for drilling a 2 to 3cm slit that essentially serves as a marker.

The turret safely places the blade and picks up a 6ml cutter. The cutter creates the slit to allow the toe-board wood to sit on top of the board without hindrance from the hinges. The hinges go into the slit.

It then replaces the 6ml cutter with a 6ml drill, which drills a hole through the board, below the slit, to allow the hinges to be attached and riveted.

Step 3: The Metal Man

Using the slit that serves as a marker that was made in step 2, the toe-board planks are handed to The Metal Man. He uses that marker to cut off the slight excess after the two holes for the hinge attachment area.

Step 4: Riveting the Hinges

Two pieces of toe-board are placed next to each other, joined by a hinge that is riveted together. This hinge allows the shorter side of the toe-board to fold into itself. Once the smaller folding part is completed, the longer parts are riveted to additional hinges.

Step 5: Quality Control & Finishing Touches

Like with all components of our scaffold towers, they undergo quality control to ensure they meet our high standards. And, once it’s stamped, it’s available for one of you lucky people to buy it.