Selecting the right scaffolding equipment is crucial for ensuring safety on construction sites. Using the wrong equipment can lead to accidents and injuries, which can be devastating for workers and their families.

When it comes to how to choose a scaffold tower, several factors need to be considered, including height requirements and weight capacity. It’s essential to assess the specific needs of your project to ensure that you’re using the most suitable equipment.

By taking the time to carefully select the right scaffold tower, you can help prevent accidents and ensure a safe working environment.

Key Takeaways

- Assess your project’s specific needs before selecting scaffolding equipment.

- Consider factors such as height requirements and weight capacity.

- Using the right scaffolding equipment can help prevent accidents and injuries.

- Carefully selecting the right scaffold tower is crucial for ensuring a safe working environment.

- Prioritise safety when choosing scaffolding equipment.

Choose A Scaffold Tower Basics

Understanding the basics of scaffold towers is key to ensuring safety and efficiency on site. A scaffold tower is a versatile and essential tool for many industries, providing safe access to high areas.

What Is a Scaffold Tower?

A scaffold tower, also known as a mobile access tower, is a type of lightweight scaffolding system, usually made from aluminium. It is designed to provide a safe working platform at height, allowing workers to perform tasks efficiently.

Common Uses and Applications

Mobile scaffold towers are popular for tasks such as drylining, plastering, and painting and decorating. They are ideal for use in a variety of settings, including construction sites, maintenance projects, and industrial environments.

Key Components of a Quality Tower

A quality scaffold tower consists of several key components, including a sturdy base, a robust frame, and a safe working platform. The tower should also be equipped with guardrails and toe boards to prevent falls.

| Component | Description | Importance |

|---|---|---|

| Sturdy Base | Provides stability and prevents the tower from tipping | High |

| Robust Frame | Supports the weight of workers and equipment | High |

| Safe Working Platform | Provides a secure area for workers to perform tasks | High |

| Guardrails and Toe Boards | Prevents falls from height | Critical |

As a leading provider of scaffold towers, we understand the importance of quality and safety. “A good scaffold tower is not just about providing access; it’s about ensuring the safety and well-being of workers,” says a industry expert.

Safety Standards and Regulations in the UK

Understanding and complying with UK safety regulations is essential for safe working practices at heights. The UK has a robust framework to ensure the safety of workers using industrial tower scaffolds.

Work at Height Regulations 2005

The Work at Height Regulations 2005 require employers to comply with specific safety guidelines when working at heights. This includes ensuring that scaffold towers are erected, used, and dismantled safely.

BS EN1004 Certification

Scaffold towers must meet the BS EN1004 certification standard, which outlines the requirements for the design, construction, and testing of mobile access and working towers.

PASMA Training Requirements

PASMA (Prefabricated Access Suppliers’ and Manufacturers’ Association) training is crucial for individuals who erect and dismantle scaffold towers. PASMA training ensures that workers understand the safe use and assembly of these structures.

Risk Assessment Considerations

Conducting a thorough risk assessment is vital before using a scaffold tower. This involves identifying potential hazards, assessing the risks, and implementing measures to mitigate them.

By adhering to these safety standards and regulations, employers can significantly reduce the risks associated with working at heights. It is essential to stay informed about the latest regulations and best practices to ensure a safe working environment.

Types of Scaffold Towers Available

Scaffold towers come in a variety of designs, each tailored to specific tasks and environments, ensuring that there’s a suitable option for every job. Whether you’re working on a construction site, maintenance project, or DIY task, understanding the different types of scaffold towers is essential for safe and efficient work.

Mobile Scaffold Towers

Mobile scaffold towers are designed for ease of movement around the workplace. They are typically equipped with wheels, allowing workers to quickly reposition them as needed. This type of scaffold tower is ideal for tasks that require frequent relocation, such as painting or maintenance work. As one industry expert notes, “Mobile scaffold towers offer the flexibility and convenience that many modern workplaces need.” Their versatility makes them a popular choice among contractors and DIY enthusiasts alike.

AGR Towers

Static Scaffold Towers

Static scaffold towers, on the other hand, are fixed in one location and are often used for tasks that don’t require frequent movement, such as bricklaying or roofing. They provide a stable working platform and are typically more robust than their mobile counterparts. “Static scaffold towers are the backbone of many construction projects,” says a seasoned contractor. Their stability and reliability make them indispensable for heavy-duty applications.

Folding Scaffold Towers

Folding scaffold towers are designed for convenience and storage. They can be easily folded and transported to different locations, making them ideal for jobs that require a scaffold tower to be moved frequently.

Industrial Scaffold Towers

Lewis towers are BSi kitemarked to EN1004. Making and selling high-end quality industrial towers and other access equipment since 2004!

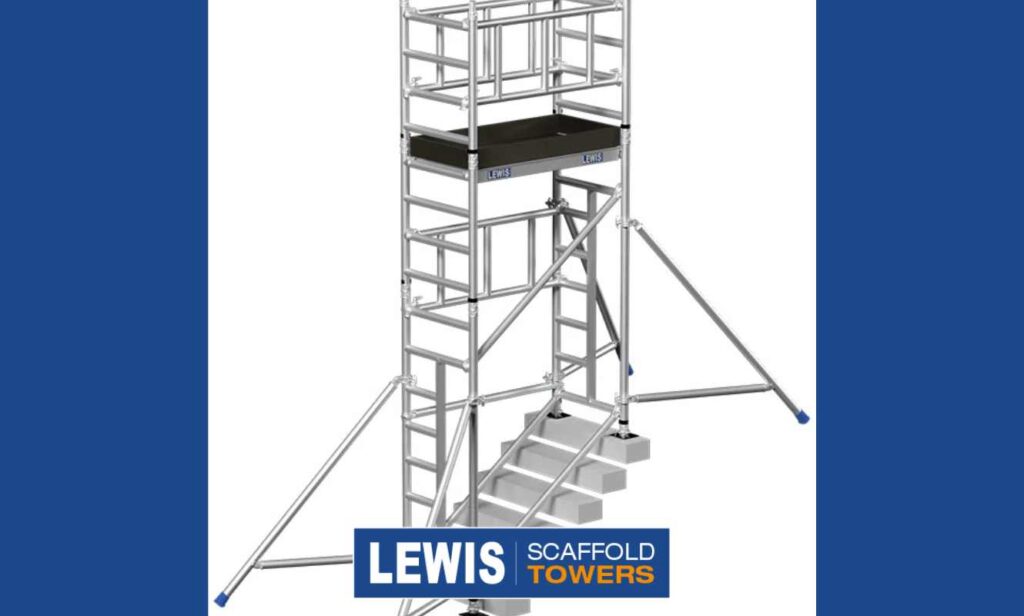

Stairwell Access Towers

Stairwell access towers are specifically designed to provide safe access to stairwells and other confined areas. They are typically narrower than standard scaffold towers, allowing them to fit into tight spaces. “Stairwell access towers are crucial for ensuring safe access to areas that are otherwise difficult to reach,” notes a safety expert.

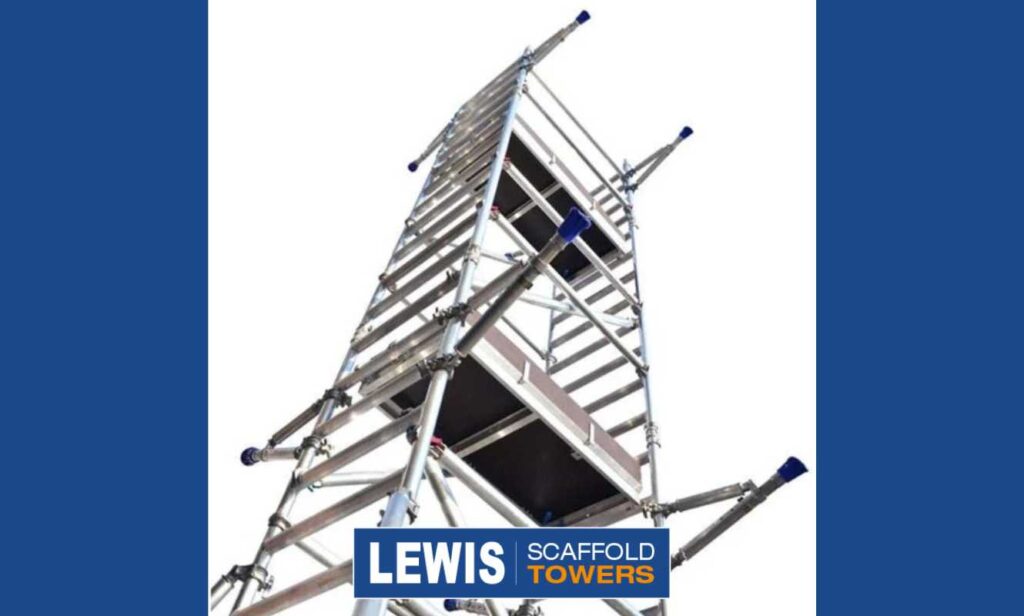

Cantilever Scaffold Towers

Cantilever scaffold towers offer a unique design that allows workers to access areas that are otherwise hard to reach, such as building facades or overhangs. They are particularly useful in situations where traditional scaffold towers cannot be used. As highlighted by a construction manager, “Cantilever scaffold towers provide the flexibility to work around complex architectural features.”

In conclusion, the diverse range of scaffold towers available means that there is a suitable option for every job, whether it’s a construction project, maintenance task, or DIY endeavor. By understanding the different types of scaffold towers, workers can choose the most appropriate one for their needs, ensuring safe and efficient work.

How to Choose a Scaffold Tower Based on Height Requirements

To ensure safe and effective working conditions, it’s crucial to choose a scaffold tower that meets your height requirements. When selecting a scaffold tower, understanding the differences between platform height and working height is essential.

Determining Your Required Working Height

The working height of a scaffold tower is the maximum height at which a person can work comfortably. It’s typically calculated by adding the platform height to the user’s height, considering factors like the need to reach overhead or work at an angle. For most applications, a general rule of thumb is to ensure the working height is at least 1-2 meters above the highest point of work.

For instance, if you’re working on a project that requires accessing a ceiling that’s 4 meters high, you’ll need a scaffold tower with a working height of at least 6 meters, assuming you’re working at or near the top platform level. Always consider the specific task requirements and the height of the personnel to determine the appropriate working height.

Adjustable Height Options

Many modern scaffold towers, especially lightweight scaffold towers, offer adjustable height options. This feature allows you to customize the tower to fit different tasks and environments. Adjustable heights can be achieved through various mechanisms, such as telescoping or modular designs.

A notable benefit of adjustable height scaffold towers is their versatility. For example, a tower that can be adjusted from 4 to 6 meters can be used for a variety of tasks, from maintenance work to construction projects, making it a valuable asset for any business.

| Platform Height (m) | Working Height (m) | Typical Application |

|---|---|---|

| 2.0 | 4.0 | Maintenance, minor repairs |

| 3.0 | 5.0 | Painting, decorating |

| 4.0 | 6.0 | Construction, major repairs |

Ceiling and Overhead Restrictions

In areas with low ceilings or overhead obstructions, such as power lines or structural beams, it’s crucial to consider these restrictions when choosing a scaffold tower. Some towers are designed to be more compact or have features that mitigate these issues.

“Scaffolds must be designed, erected, altered and dismantled only by competent people and the work should be carried out under the direction of a competent supervisor.

All scaffolding must be erected, dismantled and altered in a safe manner. “

By carefully considering your height requirements, adjustable height options, and any ceiling or overhead restrictions, you can select a scaffold tower that is both safe and effective for your specific needs.

Weight Capacity and Load-Bearing Requirements

A sturdy scaffold tower must be able to support the weight of users, equipment, and materials, making weight capacity a key consideration. Ensuring that your scaffold tower can handle the required load is crucial for maintaining a safe working environment.

Understanding Load Ratings

Load ratings are critical in determining the maximum weight a scaffold tower can safely support. These ratings are typically provided by the manufacturer and take into account various factors, including the tower’s design and materials.

Single vs. Double Width Platforms

The width of the platform is a significant factor in determining the load-bearing capacity. Single width platforms are suitable for lighter tasks, while double width platforms offer greater stability and can support more weight.

| Platform Type | Load-Bearing Capacity | Suitable Tasks |

|---|---|---|

| Single Width | Up to 200 kg | Light maintenance, painting |

| Double Width | Up to 400 kg | Heavy maintenance, construction |

Number of Users and Equipment Weight

When calculating the total weight, it’s essential to consider both the number of users and the weight of any equipment or materials being used. This ensures that the scaffold tower’s weight capacity is not exceeded.

Safety Factors in Load Calculations

Safety factors are incorporated into load calculations to account for unexpected loads or stresses on the scaffold tower. A higher safety factor provides greater assurance against potential failures.

By carefully considering the weight capacity and load-bearing requirements, you can select a sturdy scaffold tower that meets your needs while ensuring a safe working environment.

Material Options for Different Applications

Different materials used in scaffold towers offer unique benefits and drawbacks that must be considered when selecting the right equipment for a project.

Lightweight Aluminium Scaffold Towers

Aluminium scaffold towers are popular due to their lightweight nature, making them easy to transport and assemble on site. This material is particularly beneficial for projects where mobility is key. The aluminium scaffold tower is ideal for tasks that require frequent repositioning.

Non-Conductive Fibreglass Options

Fibreglass scaffold towers are another option, especially for work near power lines or electrical equipment, as they are non-conductive. This feature enhances safety in hazardous environments.

Heavy-Duty Steel Alternatives

Steel scaffold towers, while heavier, offer superior strength and durability, making them suitable for heavy-duty applications and load-bearing tasks.

Material Durability and Weather Resistance

The durability of a scaffold tower is significantly influenced by its material. For instance, aluminium is resistant to corrosion, while steel may require additional coatings to protect against rust. Fibreglass, on the other hand, is resistant to both corrosion and electrical conductivity.

Maintenance Requirements by Material

Maintenance needs vary by material; aluminium towers generally require less maintenance compared to steel, which may need regular inspections for rust. Understanding these requirements is crucial for long-term cost-effectiveness.

Portability, Storage and Transportation Factors

When selecting a scaffold tower, it’s crucial to consider its portability, storage, and transportation requirements to ensure it meets your project’s needs. A scaffold tower that is easy to transport and store can significantly enhance the efficiency and cost-effectiveness of your operations.

Folding and Collapsible Designs

One of the key features to look for in a portable scaffold tower is a folding or collapsible design. This feature allows the tower to be easily compacted, making it simpler to transport and store. For instance, a folding scaffold tower can be quickly reduced in size, enabling it to fit into smaller vehicles or storage areas.

Weight Considerations for Transport

The weight of the scaffold tower is another critical factor. Lighter towers made from materials like aluminium are easier to transport, especially for teams that need to move equipment frequently around the site. However, it’s essential to balance weight with the required strength and stability.

Storage Space Requirements

Before purchasing or hiring a scaffold tower, consider the storage space available on your site or in your facility. A compact, foldable design can significantly reduce the storage space needed, making it an attractive option for projects with limited space.

Wheel Quality and Locking Mechanisms

For mobile scaffold towers, the quality of the wheels and their locking mechanisms is vital. Sturdy, lockable wheels ensure that the tower can be moved safely and remain stable when in use. This feature is particularly important for towers that need to be repositioned frequently.

Assembly and Ease of Use Considerations

Ease of assembly is a key consideration when choosing a scaffold tower, as it directly affects the speed and safety of your work. A well-designed scaffold tower can significantly reduce the time and effort required for assembly and dismantling, thereby improving overall project efficiency.

Tool-Free Assembly Systems

Many modern scaffold towers feature tool-free assembly systems, which simplify the process and reduce the risk of losing essential tools. These systems often include quick-lock mechanisms and pre-assembled components that make it easier for workers to assemble the tower correctly and safely.

One-Person vs. Two-Person Assembly

The number of people required for assembly can impact both safety and cost. Some scaffold towers are designed for one-person assembly, which can be particularly useful for smaller projects or when labour resources are limited. However, larger or more complex towers may require two or more people to assemble safely.

Stabiliser and Outrigger Setup

Ensuring the stability of the scaffold tower is crucial for safe working practices. Stabilisers and outriggers play a vital role in this, and their setup should be straightforward and clearly documented in the manufacturer’s instructions.

| Feature | Importance | Benefit |

|---|---|---|

| Tool-Free Assembly | High | Saves time and reduces tool loss |

| One-Person Assembly | Medium | Reduces labour costs |

| Stabiliser Setup | High | Enhances safety and stability |

Platform and Guardrail Installation

The installation of platforms and guardrails is a critical aspect of scaffold tower assembly. These components must be securely attached to ensure the safety of workers using the tower.

Time Required for Setup and Dismantling

The time taken to set up and dismantle a scaffold tower can significantly impact project timelines. Towers with intuitive designs and clear instructions can reduce this time, helping to keep projects on schedule.

By considering these factors, you can choose an adjustable scaffold tower that not only meets your project’s height requirements but also enhances ease of use and overall safety.

Budget Considerations When You Choose a Scaffold Tower

Budget considerations are paramount in the decision-making process for scaffold tower selection. When evaluating options, it’s essential to consider not just the initial cost but also the long-term implications of your choice.

Purchase vs. Hire Cost Analysis

One of the primary decisions you’ll need to make is whether to purchase or hire a scaffold tower. Purchasing can be more cost-effective in the long run if you have frequent or ongoing needs. However, hiring can be more suitable for one-off projects or when storage space is a concern.

- Purchase Costs: Include the initial outlay, maintenance, and storage.

- Hire Costs: Encompass rental fees, delivery, and pickup charges.

Value for Money Assessment

Assessing the value for money involves considering the quality, durability, and performance of the scaffold tower. A cheaper option might not always be the most cost-effective if it lacks durability or requires frequent repairs.

Additional Accessories and Their Costs

Additional accessories such as stabilizers, guardrails, and platform boards can add to the overall cost. It’s crucial to factor these into your budget to ensure you’re getting a comprehensive solution.

Long-Term Investment Considerations

For businesses that frequently use scaffold towers, the long-term investment potential of purchasing high-quality equipment should be considered. Durable scaffold towers may have a higher upfront cost but can provide savings over time.

Insurance and Liability Factors

Insurance and liability are critical factors. Ensuring that your scaffold tower is properly insured against damage or loss, and understanding your liability in case of accidents, is vital for managing risk.

By carefully evaluating these budget considerations, you can make an informed decision that meets your needs and financial constraints.

Conclusion: Making Your Final Decision

By considering the factors outlined in this article, you can make an informed decision when choosing a scaffold tower that meets your needs. To recap, it’s essential to understand the basics of scaffold towers, adhere to UK safety standards and regulations, and select a tower that suits your height and weight requirements.

When making your final decision, consider the material options, portability, assembly, and budget. Assessing these factors will help you choose a scaffold tower that provides the necessary support and safety for your work. By weighing your options carefully, you can ensure a safe and successful project.

Ultimately, choosing the right scaffold tower requires careful consideration of multiple factors. By following the guidelines outlined in this article, you can confidently make a final decision that meets your project’s specific needs.

When you have bought your chosen scaffold tower, be sure to check out how to transport scaffold towers.

FAQ

What is the difference between a mobile scaffold tower and a static scaffold tower?

A mobile scaffold tower is designed to be moved around a site, typically with wheels or castors, whereas a static scaffold tower is fixed in one location. Mobile scaffold towers offer greater flexibility, while static scaffold towers provide greater stability.

What safety certifications should I look for when purchasing a scaffold tower?

In the UK, look for scaffold towers that meet the BS EN 1004 standard and have been certified by a recognised testing body. Additionally, ensure that the manufacturer or supplier provides adequate training and support.

How do I determine the correct working height for my scaffold tower?

To determine the correct working height, consider the height of the task or area you need to access. Ensure you add a sufficient safety margin to avoid overreaching. Refer to the manufacturer’s guidelines for specific height recommendations.

What is the importance of PASMA training for scaffold tower users?

PASMA training is crucial for ensuring that users understand how to safely assemble, use, and dismantle scaffold towers. It provides users with the knowledge and skills to identify potential hazards and take necessary precautions.

Can I use a scaffold tower on uneven or sloping ground?

Using a scaffold tower on uneven or sloping ground can be hazardous. It is essential to ensure the ground is level and firm. If necessary, use levelling devices or adjust the tower’s legs to achieve a stable position.

How do I calculate the weight capacity of a scaffold tower?

To calculate the weight capacity, consider the number of users, equipment, and materials that will be on the tower. Refer to the manufacturer’s guidelines for specific weight limits and safety factors.

What are the benefits of using an aluminium scaffold tower?

Aluminium scaffold towers are lightweight, corrosion-resistant, and easy to manoeuvre. They are ideal for tasks that require frequent repositioning or where weight is a concern.

Can I hire a scaffold tower for a short-term project?

Yes, hiring a scaffold tower is a cost-effective option for short-term projects. Many suppliers offer flexible hire periods, and some may provide delivery and collection services.

What factors should I consider when evaluating the portability of a scaffold tower?

Consider the weight, size, and wheel quality when evaluating portability. Folding or collapsible designs can also enhance portability and storage.

How do I ensure the scaffold tower is properly assembled and secured?

Follow the manufacturer’s instructions for assembly, and ensure that all components are securely locked in place. Use stabilisers and outriggers as recommended to prevent tipping or collapse.

What are the insurance and liability implications of using a scaffold tower?

Ensure you have adequate insurance coverage for the scaffold tower and its users. The supplier or manufacturer may also have liability insurance. Understand your responsibilities and obligations under the relevant regulations and guidelines.