We manufacture a range of scaffold tower frames, as they all slightly differ depending on the tower. In this blog, we explain the process of how our double-width 3T Industrial Scaffold Tower frame is made, particularly with the integrated ladder.

Step 1: The Metal Man

It all starts with The Metal Man cutting the aluminium tubes to the right size for a particular frame.

Step 2: Notching the Tubes

While The Metal Man has cut all the tubes, not all of them require notching.

The vertical aluminium tubes that represent the outskirt frame tubes remain with a smooth cut.

But the serrated tube is notched. It lies horizontally within the frame, and it’s the part users step on.

Step 3: Tower Ladder

Using our Elumatec machine, it uses a ladder stile, creates two see-through circles, and some surface circle cut-outs.

This allows the tubes to pass through the circles with holes, and surface circles, which enable a bridge to be made securely.

Step 4: Spider

Using our jig, the notched tubes and tower ladder are connected, forming what we call our spider.

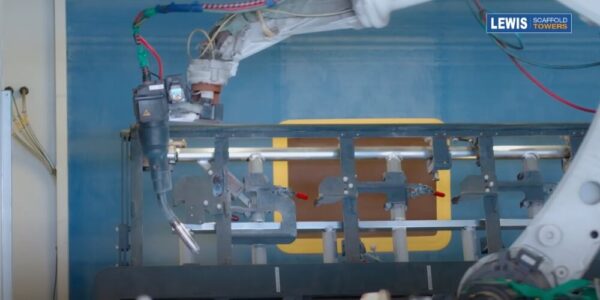

Step 5: Welding Robot Welding Scaffold Tower Frames

First things first, we add our collars, made in our foundry, to the ends of our two plain tubes that form the outskirts of the frame. Then, the first plain tube is added to the bottom of the welding robot jig.

Then, the spider is placed in the jig.

Then, the second and last plain tube with collars is added on top.

We clamp our unsung heroes, gussets, into the corners of the frames. They deserve more recognition.

Finally, the frame is topped off and boxed in with the last notched tube.

And, it’s ready to be welded once it’s all clamped.

The 3D welding robot features a jig that rotates upside down, enabling the robot to weld the other side.

Step 6: Spigot Installation

We insert the spigot into the collar end and place a pin through it.

Step 7: Quality Control & Finishing Touches

Once entirely manufactured, it goes to quality control, where the welds are checked, and it’s then ready for you to buy as part of a complete tower or a spare.